The Hidden Alchemist: How Calcium Metal Transforms Modern Steel

Walk through any modern steel mill, and you won’t see ingots of gleaming silver metal labeled “calcium.” Yet, in the final, crucial stages of producing high-quality steel, metallic calcium performs what can only be described as industrial alchemy. It is a secret weapon, a microscopic surgeon that operates

Calcium Carbide in Modern Metallurgy: From Fundamental Reactions to Industrial Precision

Introduction: The Versatile Workhorse of Steelmaking Calcium carbide (CaC₂) stands as one of the most transformative compounds in metallurgical history, bridging the gap between bulk chemistry and precision processing. This grayish-black crystalline substance, discovered accidentally by Thomas Willson in 1892 while attempti

Calcium Cored Wire: A Critical Tool for Deoxidation and Inclusion Modification in Steelmaking

In the relentless pursuit of higher quality, cleaner, and more reliable steel, modern secondary metallurgy relies on precise and efficient treatment methods. Among these, the use of calcium cored wire has become a cornerstone technology, primarily for the dual, interconnected purposes of deoxidation and inclusion modificati

How Cored Wire Injection Improves Steel Cleanliness and Casting Performance

In modern steelmaking, the demand for high-purity, high-performance steel is continuously increasing, particularly for critical applications in automotive, aerospace, and precision engineering. One of the most persistent challenges in achieving this goal is the control of non-metallic inclusions—oxide, sulfide, and other im

Meeting ASTM/EN Standards for Pipeline Steel: The Critical Role of Cored Wire Treatment

Introduction: The Global Benchmark for Pipeline Integrity Pipeline steels represent one of the most demanding applications in modern metallurgy, required to operate under extreme conditions—from sub-arctic temperatures to high-pressure sour service environments. Meeting international standards such as ASTM (American Society

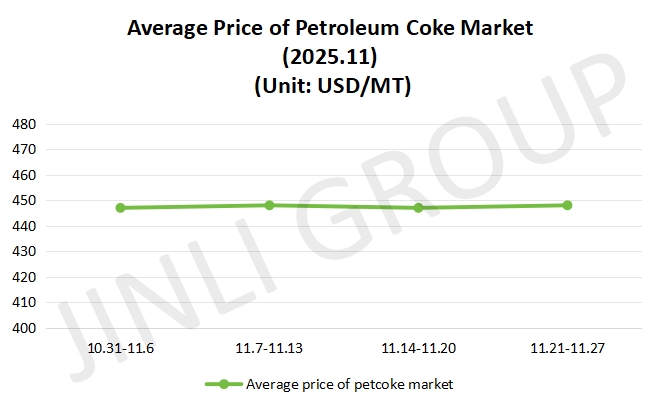

Petroleum Coke Price Monthly Analysis 2025.11

In November 2025, petroleum coke prices experienced further fluctuations and influenced by a range of factors including shifts in demand from key industries, supply chain disruptions and global economic conditions. As production levels and trade flows adjusted to market pressures, pricing trends

Optimizing Ladle Metallurgy with Tailored Cored Wire Formulations

Introduction: The Strategic Importance of Ladle Metallurgy Ladle metallurgy represents the final frontier for precision control in modern steelmaking, where chemical composition, temperature, and cleanliness are fine-tuned to meet exacting customer specifications. This secondary refining stage has evolved from simple temper

Micro-alloying via Cored Wire: Enhancing Mechanical Properties in HSLA Steels

Micro-alloying via Cored Wire: Enhancing Mechanical Properties in HSLA Steels The Modern Challenge: Achieving Strength Without Compromise High-Strength Low-Alloy (HSLA) steels occupy a critical position in modern engineering, bridging the gap between conventional carbon steels and higher-cost specialty alloys. Their applica

Advanced Inclusion Control in Steelmaking: The Role of Precision Cored Wire Injection

Introduction: The Critical Challenge of Non-Metallic Inclusions In modern steelmaking, non-metallic inclusions represent one of the most persistent challenges affecting product quality, performance, and consistency. These microscopic particles—oxides, sulfides, and silicates—can initiate cracks, reduce fatigue strength, and

5 Essential Benefits of Using Cored Wire in Modern Steelmaking

Introduction In the ever-evolving steel industry, efficiency and precision are paramount. One innovation that has transformed steel production is cored wire technology. At Jinli Group, we specialize in manufacturing high-quality cored wires designed to optimize your steelmaking processes. This article explores five essentia