The Critical Role of Fluorspar in Modern Steel Production

Fluorspar (calcium fluoride, “CaF₂”) is an essential fluxing agent in steel manufacturing, playing a pivotal role in “slag formation, desulfurization, and refractory protection”. Its unique chemical properties optimize steelmaking processes, ensuring “higher productivity, reduced energy consumption, and superior steel quality”.

Key Benefits of Fluorspar in Steelmaking

1. “Improved Slag Fluidity & Faster Refining”

– Fluorspar lowers the “melting point and viscosity of slag”, facilitating efficient removal of impurities (e.g., sulfur, phosphorus).

– Enhances “slag-metal interaction”, accelerating refining and reducing tap-to-tap time in “electric arc furnaces (EAF) and basic oxygen furnaces (BOF)”.

2. “Energy & Cost Savings”

– Reduces “specific energy consumption”by improving slag fluidity, leading to “lower power requirements” in EAF operations.

– Minimizes “lime (CaO) consumption”, cutting raw material costs while maintaining optimal basicity.

3. “Enhanced Steel Quality & Yield”

– Promotes “effective desulfurization”, reducing sulfur content to “<0.005%” for high-grade steel production.

– Improves “metal recovery rates” by minimizing iron loss in slag.

4. “Extended Furnace Lining Life”

– Acts as a “protective flux”, reducing refractory wear in high-temperature environments.

– Lowers “slag corrosiveness”, prolonging the lifespan of furnace linings and reducing downtime.

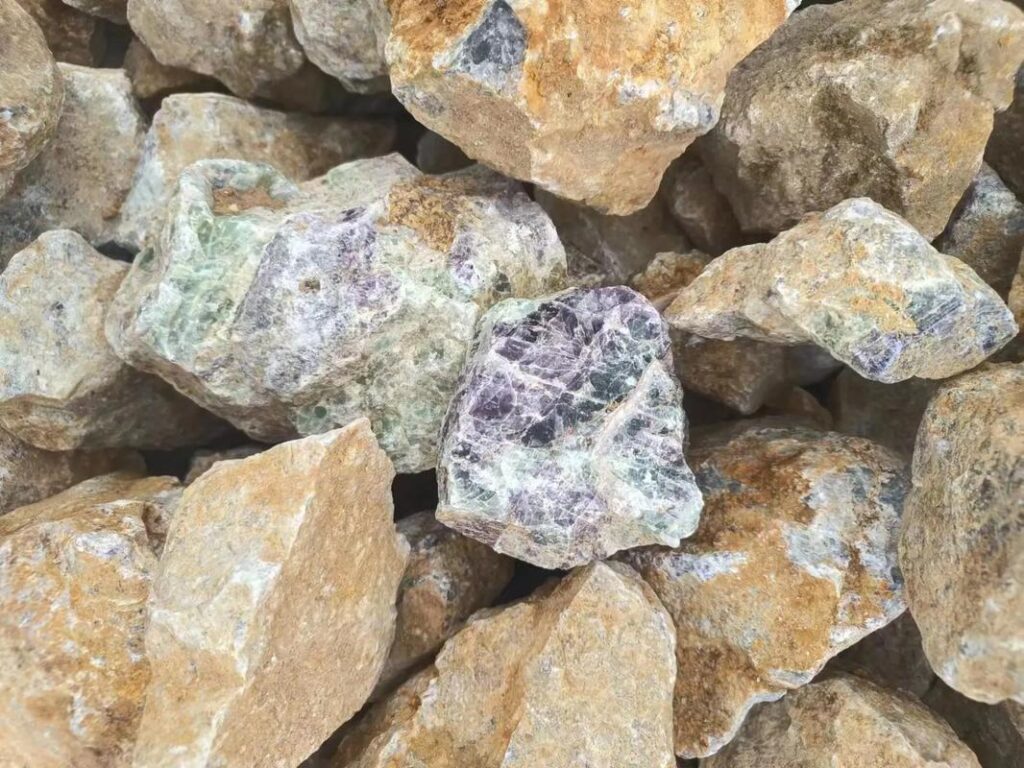

“Technical Specifications: Why Our Fluorspar Stands Out”

To maximize steelmaking efficiency, our fluorspar meets stringent industry standards:

- Parameter| Specification |

- CaF₂ Content | ≥ 85% – 97%

- SiO₂| ≤ 3.0%

- Sulfur (S) | ≤ 0.1%

- Phosphorus (P) | ≤ 0.05%

- Moisture | ≤ 1.0%

- Particle Size | Custom (10-100mm or powder)

- Available in “metallurgical-grade (≥85% CaF₂)”and “acid-grade (≥97% CaF₂)”, ensuring compatibility with “EAF, BOF, and ladle refining processes”.

“Case Study: Fluorspar in Action”

A leading steel mill integrated our high-purity fluorspar into their EAF operations, achieving:

✔ 12% reduction in energy consumption**

✔ 15% faster slag removal**

✔ Extended refractory life by 20%**

✔ Improved steel cleanliness (lower inclusion counts)**

Why Partner With Us?

✅ High-Purity, Consistent Supply – Rigorous quality control from mine to delivery.

✅ Technical Expertise – Customized fluorspar blends for your specific steelmaking needs.

✅ Global Logistics Network – Reliable, just-in-time delivery to minimize disruptions.