Content

The Definition Of Cored Wire

Cored wire is a kind of wire that use steel strip covered alloy powder to produce. Winding appearance looks like coil.

Description Of Cored Wire

Structure

Cored Wire is a complete, new high-tech product and emerging in recent years.

Outer layer of cored wire is steel strip whose thickness is 0.4mm approximately, inner layer covered one or several different additives such as Calcium Silicon(CaSi) powder, Ferro Calcium(CaFe) powder, Carbon(C) powder, Magnesium Silicon(MgSi) powder, Silicon(Si) powder, Sulphur(S) powder, Aluminium(Al) powder, Silicon Barium(BaSi) powder, Pure Calcium(Ca) powder, etc. And using it to make all kinds of cored wire whose diameter is 9mm, 13mm or 16mm. After producing, we pack cored wires into rolls and packed with iron or wooden pallet, steel cage and plastic film.

Working Principles And Functions

Steel mills usually feed all kinds of cored wire into ladle by feeding machine. During this process, it makes chemical reaction between cored wire and ladle. And it has effect on deoxidation and desulphurization by chemical reaction. So achieve the goal that clean liquid steel.

Steel strip in outer layer is cold-rolled strip steel, it occupied 45% approximately and core powder in inner layer is about 55%. The weight of steel strip and core powder must be within a fixed range to reach using requirements of steel mills. Core powder should be filled in steel strip fully so that ensure not to meet broken wires, cracked steel strip and other problems during using process. Only after making cored wires using steel strip, core powder can be fed into ladle by feeding machine.

Outer steel strip covered inner core powder, feeding machine can feed cored wire into bottom of ladle. And then outer steel strip is melted and changed into molten steel to increase ferro element content in ladle, inner core powder and impurities in ladle deoxidate, desulphurize and make any other chemical actions and adjust element content in ladle.

During producing process, cored wires are new type save-energy products with low energy consumption and low pollution without smelting. For users——steel mills, cored wire can have effect on saving energy, environmental protection, deoxidation, desulphurization and purifying liquid steel.

Fig.1 Cored Wire

Producing Techniques

Producing process: Firstly, we take steel strip into shaping equipment to shape primarily. Then, add core powder to steel strip by related hopper. Core powder include but not limited to: CaSi powder, CaFe powder, C powder, MgSi powder, Si powder, S powder, Al powder, BaSi powder, Pure Ca powder. After folding, sealing and other procedures, we get a random length cored wire. However, it doesn’t finish. They will be rolled to a regular cored wire coil by rolled machine. At last, we use pallets and films to pack it respectively.

Using process: Pass cored wires through surface of liquid steel under constant speed by feeding machine in foundry or steel mill process station. With steel strip melted continuously, core powder in inner cored wire fed into liquid steel or molten steel gradually. It achieves the goal that clean the liquid steel or molten steel by interaction.

Especially, in cored wire produced process, do not have any continuous casting process, only one or several additives covered into steel strip.

Categories Of Cored Wire

According to distinct alloy powders, cored wire can be divided in: CaSi cored wire, CaFe cored wire, Pure Ca cored wire, CaAl cored wire, MnSi cored wire, CaSiBa cored wire, AlBa cored wire, FeTi cored wire, rare earth cored wire, etc.

By above introducing, more usual used cored wires among introduced cored wires are Carbon cored wire, CaSi cored wire and Pure Ca cored wire. Carbon cored wire was also called graphite cored wire, core powder of C cored wire is semi-graphite powder. Calcium and Silicon usual content in CaSi cored wire is 3060 respectively. Pure Ca cored wire refer to calcium content above 98% usually.

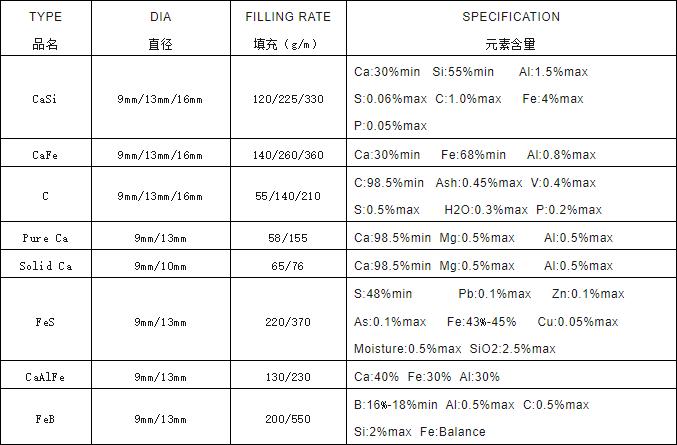

Fig.2 Categories and specifications of cored wire JINLI GROUP produced

Uses Of Cored Wire

Cored wire usually can be used in steelmaking and steel industry field.

Cored wires can add smelted material into molten steel more effectively during steelmaking or casting process. When we use cored wires, professional feeding machine will be also used. Professional feeding machine can feed cored wire into ideal position of ladle. After surface of cored wire melted, core powder dissolved sufficiently in ideal position and made chemical reaction. It is effective to avoid reacting with air and slags. Improving absorption rate of smelted materials, using as deoxidizer, desulphurizer and alloy additive. It can change forms of liquid steel inclusions and improve quality of steelmaking and casting products. However, it has a premise that you must use professional feeding wire equipment. If you do not have feeding wire equipment, it will be troublesome when you use.

The reason why it will be troublesome as below:

- Feeding wire approach can adjust finely for compositions in molten steel, make alloy recovery improved sharply;

- Molten steel reacts smoothly and avoid oxidizing secondly. Inclusions come-up rate is prompt and purify equably;

- Using feeding wire approach can avoid gas into molten steel;

- Strong suitability, less one-off investment, small occupied area and extensive use;

- Simple equipments, convenient operation and do not have environmental contamination.

Applications And Features Of Cored Wire

Cored wire is suitable for deoxidation, desulphurization during smelting process. It can improve performance and plasticity of steel, impact toughness and liquidity of molten steel. What’s more, cored wire can be also fed into molten steel directly and melted immediately and distributed equably. With alloy steel development, premium alloy steel, grade steel drastic increment and outer furnace refined technique consecutive consummation, promotes feeding cored wire technology exploit successfully. Using feeding technique is more superior than adding alloy blocks directly. Cored wire produced by JINLI GROUP in conformity with National Standard Regulation, it has a lot of merits such as feed powder uniformly, low broken wire rate and so on. CaSi cored wire core powder technique is an outer furnace refined method, it is used in feeding wire technique of contemporary steelmaking. Alloy cored wire used in steelmaking to purify the molten steel, change form of inclusions, improve liquid steel castability and mechanical property. And it can improve ferroalloy recovery apparently, reduce costs of steelmaking, its economical effect is prominent.

Preponderance Of Cored Wire

We will take C cored wire as an example to introduce its preponderance as follows.

Carburized Cored Wire is also called Carbon Cored Wire, it can replace recarburizer to carburize when it need in foundry process. That is main function of carbon cored wire.

Core powder of carbon cored wire is graphite powder. Graphite powder, needless to say, it is an excellent product in contemporary market. It contains sufficient C element. It must be also pure, dry, low moisture without impurities. And then, rolled steel strip with carbon powder to standard diameter cored wire, outside smoothly without cracking.

Carbon cored wire can be fed into molten steel by equipment. Because of steel strip, it avoids wasting. After it reached molten steel, steel strip melted by high temperature. At this moment, carbon powder and molten steel made chemical reaction, making carburizing process. In addition, melted steel strip isn’t wasted, it increases iron content of molten steel.

As carbon cored wire appearance, it is a new choice to many foundries. Compared with powder granulated recarburizer, carbon cored wire is not only secure but also protect environment friendly without wasting, reduce costs and increase efficiency. It has become famous product in the foundry market.

In conclusion, different kinds of cored wires have their individual preponderance, you should choose the most suitable cored wires for yourself by your current conditions and requirements. JINLI GROUP can provide premium cored wire and the best service experience to our clients. Our clients cooperated with us are very satisfied with our products and service. We are looking forward to cooperating with you in the future!

If you have any questions or needs, please contact us without any hesitation. We will revert as soon as possible.