Introduction

In modern steelmaking, especially in secondary metallurgy, the use of cored wire has become an indispensable technique for precise and efficient alloying, deoxidation, desulfurization, and inclusion morphology control. This technology involves feeding a metallic sheath filled with powdered or granular additives into the molten steel. The choice of cored wire type is critical, as it directly impacts the final steel quality, production cost, and process efficiency. This article explores the metallurgical functions and typical application scenarios of three common cored wire types: Calcium-Silicon (Si-Ca), Calcium-Iron (Ca-Fe), and Carbon (C-Wire).

1. Calcium-Silicon (Si-Ca) Cored Wire

Metallurgical Functions:

Calcium-Silicon wire is the most widely used type for advanced steel quality control. Its primary functions are:

Inclusion Morphology Control: This is its most critical role. Aluminum-killed steels often form solid, high-melting-point alumina (Al₂O₃) inclusions, which can clog nozzles and cause brittleness. Calcium from the wire reacts with alumina to form liquid calcium aluminate (e.g., 12CaO·7Al₂O₃), which is spherical and remains liquid during casting. This transformation prevents nozzle clogging and improves the castability of the steel.

Deoxidation and Desulfurization: Calcium is a strong deoxidizer and desulfurizer. It helps in further reducing the oxygen and sulfur content in the molten steel, leading to cleaner steel with improved purity.

Microalloying:It introduces silicon and calcium into the melt, which can enhance the steel’s mechanical properties.

Application Scenarios:

Production of High-Grade Aluminum-Killed Steels: Essential for manufacturing steels for critical applications such as deep-drawing automotive sheets, pipeline steels (e.g., API X70/X80), and other high-strength low-alloy (HSLA) steels.

Continuous Casting of Aluminium-Killed Steels: Used to ensure smooth continuous casting by preventing the buildup of alumina clusters in the submerged entry nozzle (SEN).

Stainless Steel Production: Used to improve fluidity and inclusion control.

2. Calcium-Iron (Ca-Fe) Cored Wire

Metallurgical Functions:

Ca-Fe wire shares some functions with Si-Ca wire but has distinct characteristics due to its different composition.

·Powerful Desulfurization: The primary function of Ca-Fe wire is deep desulfurization. The high reactivity of pure calcium vapor allows for extremely efficient sulfur removal, achieving very low final sulfur levels (<0.005% or even lower).

·Deoxidation and Inclusion Modification: Similar to Si-Ca wire, it modifies alumina and sulfide inclusions, making them less harmful. However, its efficiency in forming liquid inclusions is highly dependent on the steel’s aluminum content and temperature.

·No Silicon Addition: Unlike Si-Ca, it does not introduce silicon into the steel. This is a crucial advantage when producing ultra-low carbon or silicon-sensitive steels.

Application Scenarios:

Production of Ultra-Low Sulfur Steels: Ideal for applications where superior toughness and resistance to Hydrogen-Induced Cracking (HIC) are required, such as in heavy plates for offshore platforms and sour service pipelines.

Silicon-Restricted Steels:Used for steels like Interstitial-Free (IF) steels and Electrical Steels, where even small silicon additions from Si-Ca wire are undesirable for magnetic or formability properties.

Secondary Refinement after Vacuum Degassing: Often used as a final treatment to achieve the deepest possible desulfurization and inclusion shape control.

3. Carbon (C-Wire) Cored Wire

Metallurgical Functions:

Carbon cored wire serves a more straightforward but equally vital purpose: precise carbon content adjustment.

·Precision Carburization:The primary function is to increase the carbon content of molten steel with high accuracy and yield. The carbon powder, encapsulated in a steel sheath, dissolves efficiently upon immersion, minimizing losses to the atmosphere (compared to adding loose carburizers).

·Cost-Effective Alloying: It is a highly efficient and economical method for making fine adjustments to the final chemical composition, especially to meet the upper limit of a carbon specification.

·Slag Foaming (in EAF/LF): In Electric Arc Furnace (EAF) and Ladle Furnace (LF) operations, carbon wire can be used to inject carbon into the slag to generate CO gas, promoting foamy slag practice which improves energy efficiency and protects the refractory.

Application Scenarios:

Correcting Under-Carburized Heats:** Commonly used to rectify situations where the carbon content is below the target range before tapping or casting.

Production of Medium and High-Carbon Steels:Used in the manufacturing of spring steels, tool steels, and bearing steels where precise carbon control is paramount.

Ladle Furnace (LF) Operations:A standard tool for trim carburization during the ladle treatment stage.

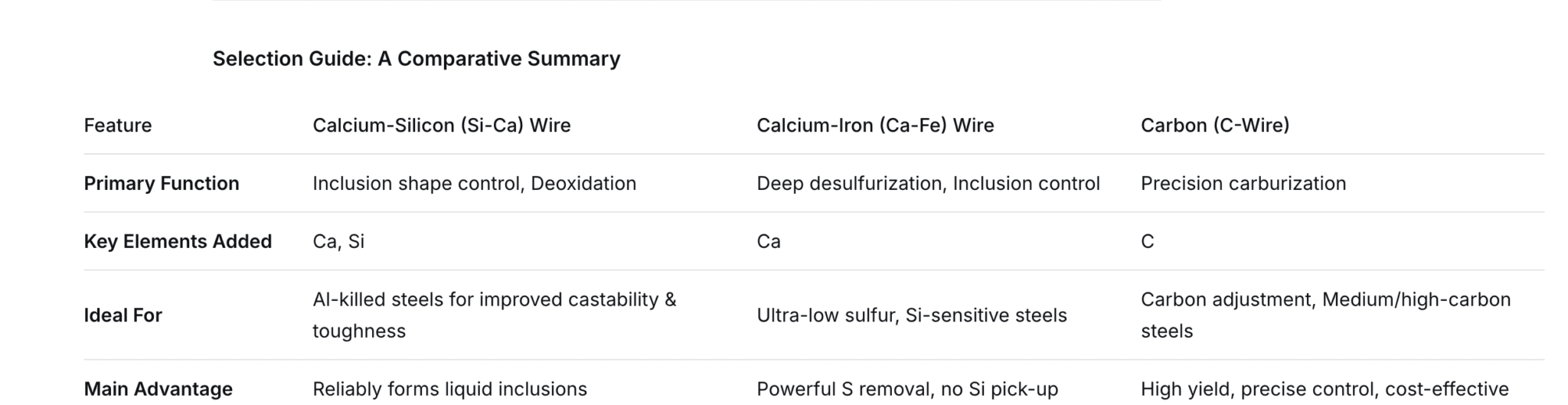

Selection Guide: A Comparative Summary

Conclusion

The selection of the appropriate cored wire is a strategic decision in secondary steelmaking. “Calcium-Silicon (Si-Ca) wire” is the go-to solution for robust inclusion morphology control in a wide range of high-quality steels. “Calcium-Iron (Ca-Fe) wire” is specialized for achieving ultra-low sulfur levels and is preferred for silicon-restricted grades. Meanwhile, “Carbon (C-Wire)” is a dedicated and efficient tool for precise carbon adjustment. Understanding the distinct metallurgical functions of each type allows metallurgists to optimize their processes, enhance final product quality, and control production costs effectively.