- Product

- Alloy Cored Wire

- Normal Cored Wire

Normal Cored Wire

These cored wires are normally used by our partners. And these also widely used in steel making plants.

- calcium silicon cored wire ( CaSi cored wire )

- ferro calcium cored wire ( CaFe cored wire )

- solid calcium cored wire

- pure calcium cored wire

- carbon cored wire ( C cored wire )

- ferro boron cored wire ( FeB cored wire )

- pure sulfur cored wire ( S cored wire )

- Please check more cored wires

More Specifications For Normal Cored Wire

Our standard specifications are as below. Our standard size is OD 1100mm, ID 550mm, Height/Width 1100mm.

We list all of the applications for different kinds of alloy cored wires to help you make reference.

We can adjust coil weight and size according to your request.

Please tell us your requests .

Ca 30%min, Si 58%min, Al 1.5%max, S 0.006%max, C 1%max, P 0.05%max. Diameter 9/13/16mm.

- Retains the deoxidising properties of calcium silica and the desulphurising and denitrifying properties of calcium in calcium silica alloys

- Increase the reaction time and effect of calcium elements

- CaSi cored wire can improve the alloy yield in the steel making process, reduce the cost, shorten the smelting time and precisely control the composition

Calcium Silicon Cored Wire

Ca30%min, Fe 70%max, Al 0.8%max. Diameter 9/13/16mm

- Used in low carbon, ultra low carbon and low silicon steel grades and pure steel with strict requirements on the shape and quantity of inclusions for calcium treatment

- As a deoxidising agent, CaFe cored wire can reduce the blockage of water ports

- After adding calcium to the steel, ferro calcium cored wire can avoid the formation of long strips of sulphide inclusions and improve the anisotropy of the steel

- The yield of metals, rare earths and other elements is increased to ensure the stability of the composition

- Reduces the addition of precious elements and reduces refining costs

Ferro Calcium Cored Wire

Ca 98.5%min, Mg 0.85%max, Al 0.8%max. Diameter 9/11mm

- The feeding process does not bring in granular oxides and is more conducive to the production of pure steel

- Reduces and eliminates clogging of the water outlet in continuous steel casting

- Thicker strip and high density pure calcium cores can feed calcium deeper into the steel and stay below the critical depth for longer, with higher calcium recovery rates

- Calcium wire is fed lower than other cored wires and the recovery rate is the highest

Solid Calcium Cored Wire

Ca 98.5%min, Mg 0.85%max, Al 0.8%max. Diameter 9/13mm

- Increased penetration of the steel

- Bringing in the calcium metal particles powder, which can cool down the local steel and increase the thermal resistance of the calcium metal line

- Reduced calcium metal vapourisation and increased solubility of calcium in the steel

- Higher calcium yield than other wires

Pure Calcium Cored Wire

C 98.5%min, Ash 0.7%max, V.M. 1%max, S 0.5%max, Moisture 0.5%max. Diameter 9/13/16mm

- Increase the carbon element, instead of carbon enhancer

- Used in smelting industry, steel making and casting

- Supplement the carbon content of steel in steelmaking, make the elements more uniform and improve the hardness of steel

- When casting, it plays the role of breeding, spheroidization, etc.

- In the production of graphite cast iron and ductile and grey cast iron, to improve the quality of castings by increasing the crystallization of spherical grinding and improving the distribution of graphite

Carbon Cored Wire

B 15%-20%, Al 0.5%max, C 0.5%max, Si 2%max, Fe balance. Diameter 9/13mm

- When producing low carbon continuous casting billets, the element of nitrogen can be eliminated

- The addition of ferro boron in high-quality alloys can partially replace chromium, nickel, molybdenum and other alloying elements without reducing the performance of steel products

- Adding boron to non-oriented silicon steel can improve the magnetic properties of silicon steel sheets, reduce magnetic aging and reduce iron loss

- Improve the cracking phenomenon on the surface of billets and increase the yield of billets

Ferro Boron Cored Wire

S 99%min. Diameter 9/13mm

- Adjust and control the sulphur content in the steel or iron liquid

- To blow argon gas at the bottom of the ladle when feeding the sulphur cored wire, which can improve the material of easy-to-cut steel, while also reducing costs

- In stainless steel with sulphur, help to improve the cutting properties of finished steel, change the shape of sulphur inclusions, improve processability

Pure Sulfur Cored Wire

Seamless Cored Wire

- The calcium wire has a metal calcium wire content of about 80%, and there are gaps inside after wrapping; the seamless calcium wire has a metal calcium wire content of 98%, and there are almost no gaps after wrapping

- The calcium absorption rate of seamless calcium wire is high and the calcium increase in the steel is stable

- Seamless calcium wire reduces the operational intensity of the steel mill and effectively reduces the production cost of the steel mill

Seamless Cored Wire

Other Cored Wire

- In addition to these cored wires, we also produce other types of cored wires. Please click on the button above to view them

- We can customise different types of cored wire to meet the different production needs of our customers, depending on the type of steel they produced

Other Cored Wire

播放视频

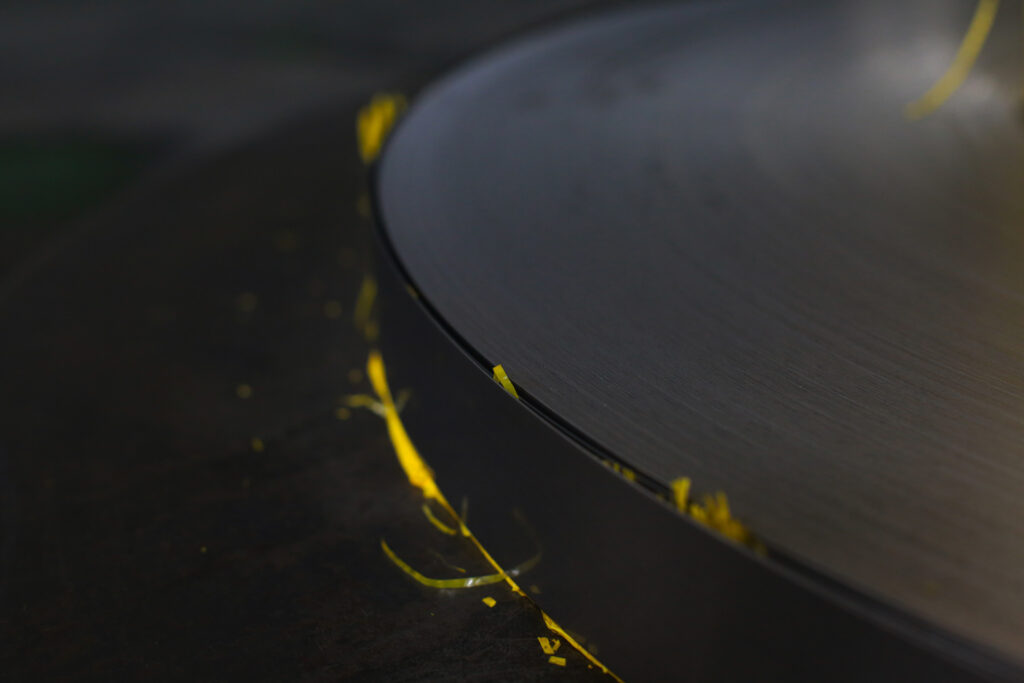

Live video of a customer using our cored wire

Many of our partners are satisfied with our cored wires.

We record the use of our products during our partner visits.

Professional technical and sales staff to provide you with the most professional service

- We have fifteen shipping lines and more than 80 people in our alloy cored wire factory. Our capacity is 1,500 mt/month with 11 production lines.

- Professional technicians supervise the production process, which can avoid broken wires and empty tubes, and ensure even distribution of core powder.

- A professional sales team will lead the technical staff along to the steel mill to guide the customer in its use and to learn and improve in case of problems.

- General production and use problems can be solved by our sales staff. If you need more help, you can contact our after-sales staff and have a special technician to guide you.

22 Years Experience

We have been producing alloy cored wires since 2000.

5000+ Cored Wire Orders

We successfully achieve more than 5000 orders.

Package, Storage & Delivery

- Wrap the produced cored wire on the production line by machine, evenly and neatly, and wrap it with plastic sealing film

- Weld the iron pallets according to the customer's axial requirements

- The goods are kept in a dry and safe warehouse

- Check again before delivery

Contact Us

JINLI GROUP CO.,LIMITED

Send Us Message To Get A Quick Reply