- Product

- Steel Making Related Products

- Oxygen Lance

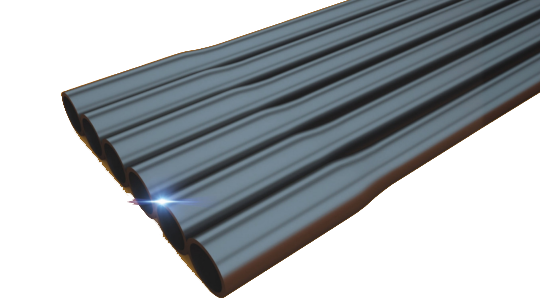

Oxygen Lance

We have a year-round relationship with many of our steel mill customers who have asked us to help them procure related products for use in steel mills. Over the years of sourcing, we have also entered into partnerships with a number of specialized companies. We can offer more competitive prices and services.

This oxygen lance company was established in 1988 and has ISO90001 certification, ISO14001 environmental management system certification and OHSAS18001 occupational health and safety management system certification. They became the largest production and manufacturing base in China in 2011.

We keep developing new products and keep selling our products to all over the world such as Europe, America, Southeast Asia and Africa. We mainly have series products such as thermic lance, oxygen lance, aluminized oxygen lance, ceramic coated oxygen lance, aluminized ceramic coated oxygen lance, underwater cutting lance, welding tube, etc.

If you need any other services, please click to find.

Or contact us directly.

Oxygen Lance

Applications

1. Transport oxygen or other gases in the electric arc furnace steelmaking, melting and refining anhydride iron in the electric arc furnace

2. Injection of other powder additives to adjust the steel grade or refine special steel

3. Clear oxygen charge furnace in the slag

4. Other uses, such as in strong heat resistance, oxidation resistance, anti-sulfuration and corrosion resistance, etc.

Features

1. Low consumption: the product comes with a pressure sleeve connector, which can be linked to use, saving cost without waste

2. High quality: All production steps from the screening of raw materials to the production of finished products are under strict quality control management

3. Low price: more advanced production equipment to form the production line, to achieve the product quality and low price

| Oxygen lance | Pressure | Length | |||

|---|---|---|---|---|---|

| DN | Inch | Outer Diameter | 5 Bar | 10 Bar | |

| 6 | 1/8 | 10 | Ca.15Nm3/h | Ca.35Nm3/h | 1000/1800/3000/6000 |

| 8 | 1/4 | 13.5 | Ca.45Nm3/h | Ca.90Nm3/h | 1000/1800/3000/6000 |

| 10 | 3/8 | 17 | Ca.90Nm3/h | Ca.180Nm3/h | 3000/5000/5500/6000 |

| 15 | 1/2 | 21.5 | Ca.160Nm3/h | Ca.290Nm3/h | 3000/5500/6000/9000 |

| 20 | 3/4 | 26.7 | Ca.360Nm3/h | Ca.700Nm3/h | 3000/5500/6000/9000 |

| 25 | 1 | 33.4 | Ca.600Nm3/h | Ca.1200Nm3/h | 3000/5500/6000/9000 |

| 32 | 1-1/4 | 42 | Ca.1200Nm3/h | Ca.2000Nm3/h | 5000/5500/6000/9000 |

| 40 | 1-1/2 | 48 | Ca.1900Nm3/h | Ca.3300Nm3/h | 5000/6000/9000/12000 |

| 50 | 2 | 60 | Ca.3100Nm3/h | Ca.5600Nm3/h | 5000/6000/9000/12000 |

| Cutting Data | Outer Diameter(mm) | Length(mm) | Iron Wire | |||

|---|---|---|---|---|---|---|

| 12 | 1800 | 2.8mm*6 | ||||

| Cutting material | Thickness(mm) | Pressure(MPa) | Cutting Time(s) | Cutting Length(mm) | Cutting Speed(mm/s) | Consumption(mm/s) |

| alloy steel plate | 20 | 0.3 | 52 | 232 | 4.5 | 9.6 |

| 0.5 | 50 | 252 | 5.0 | 10.0 | ||

| cold-roll steel plate | 20 | 0.3 | 39 | 130 | 3.3 | 12.8 |

| 0.5 | 29 | 146 | 4.7 | 17.2 | ||

| stainless plate | 5 | 0.3 | 48 | 583 | 12.1 | 10.4 |

| 10 | 0.5 | 47 | 366 | 7.8 | 10.6 | |

| aluminium plate | 5 | 0.3 | 48 | 1032 | 21.5 | 10.4 |

| 0.5 | 43 | 1059 | 33.9 | 11.6 | ||

| copper plate | 5 | 0.3 | 40 | 417 | 10.4 | 12.5 |

| 0.5 | 38 | 513 | 13.5 | 13.1 | ||

Thermic Lance

Thermic lance is the first new product with fast fusion cutting and cleaning function in China. Under the fuel of oxygen, it can immediately produce high temperature of 3600℃, so that the processed workpiece can be quickly melted and cut live to clean up and achieve the purpose of operation.

The efficacy of the thermic lance is 4-5 times higher than the efficacy of ordinary cutting tools. And the thickness of the fusion cut workpiece can reach more than 1000MM, regardless of the thickness of cleaning and perforation, which is very suitable for mobile operation.

Contact Us

JINLI GROUP CO.,LIMITED

Send Us Message To Get A Quick Reply