- Product

- Alloy Cored Wire

- Seamless Cored Wire

Seamless Cored Wire

Our seamless cored wire factory was established in 2010.

We suggest that our partners use this instead of normal cored wire.

Many of them get a higher recovery with this seamless cored wire.

- Please check more alloy cored wires

Advantages of Seamless Cored Wire

- Increase 30% of calcium recovery than normal cored wire.

- Effectively reduce spillage of liquid steel.

- Significantly improve the utilization of the ladle.

- The calcium cored wire can be used in the ordinary feeding machine to feed cored wire and suitable for all kinds of the steel grades.

- Due to the product technology advantage, reduce oxidation process, increase the storage time of calcium.

Interested in Seamless Cored Wire?

Seamless Cored Wire

- Seamless solid calcium cored wire

- Seamless calcium ferro cored wire

Our Standard Specifications

- Seamless solid calcium cored wire

Diameter: 9 mm

Thickness of strip: 1-1.2 mm

Filling rate: 57 g/m

Wire weight: 265 g/m

- Seamless calcium ferro cored wire

Diameter: 13 mm

Thickness of strip: 1-1.2 mm

Filling rate: 140 g/m

Wire weight: 365 g/m

Professional technical and sales staff to provide you with the most professional service

- We have fifteen shipping lines and more than 80 people in our alloy cored wire factory. Our capacity is 1,500 mt/month with 4 production lines for this seamless cored wire.

- Professional technicians supervise the production process, which can avoid broken wires and empty tubes, and ensure even distribution of core powder.

- A professional sales team will lead the technical staff along to the steel mill to guide the customer in its use and to learn and improve in case of problems.

- General production and use problems can be solved by our sales staff. If you need more help, you can contact our after-sales staff and have a special technician to guide you.

22 Years Experience

We have been producing alloy cored wires since 2000.

5000+ Cored Wire Orders

We successfully achieve more than 5000 orders.

Package, Storage & Delivery

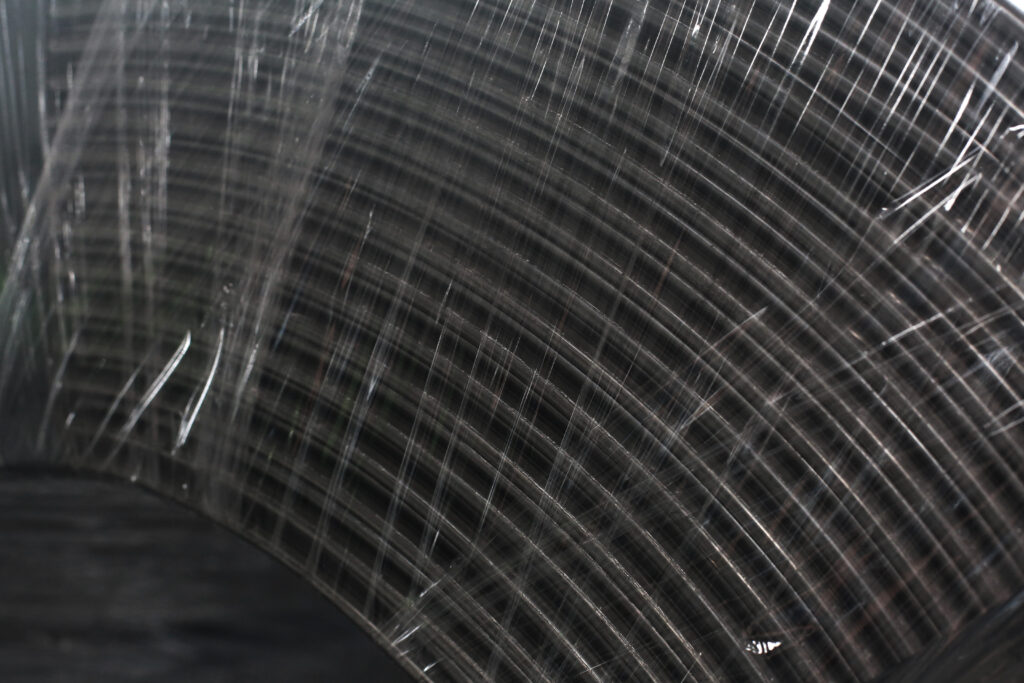

- Wrap the produced cored wire on the production line by machine, evenly and neatly, and wrap it with plastic sealing film

- Weld the iron pallets according to the customer's axial requirements

- The goods are kept in a dry and safe warehouse

- Check again before delivery

Contact Us

JINLI GROUP CO.,LIMITED

Send Us Message To Get A Quick Reply