Introduction

In modern steelmaking, the demand for high-quality steel with superior mechanical properties and cleanliness is ever-increasing. One of the most effective methods to achieve this is through the use of “pure calcium cored wire”, a crucial material in secondary metallurgy. This article explores the key benefits, mechanisms, and applications of pure calcium cored wire, demonstrating why it is an indispensable tool for steel manufacturers seeking to improve process efficiency and product quality.

Why Pure Calcium Cored Wire?

Calcium (Ca) plays a vital role in steel modification, particularly in:

– Deoxidation – Calcium reacts strongly with oxygen, reducing oxide inclusions.

– Desulfurization– It forms stable calcium sulfides (CaS), lowering sulfur content.

– Inclusion Modification – Transforms harmful alumina (Al₂O₃) inclusions into liquid calcium aluminates, improving machinability and fatigue resistance.

– Preventing Nozzle Clogging – By preventing the buildup of alumina clusters in continuous casting.

However, calcium has a low boiling point (1,484°C) and high vapor pressure, making direct addition inefficient. “Cored wire technology” solves this by delivering calcium deep into the molten steel, ensuring optimal absorption.

Key Advantages of Pure Calcium Cored Wire

1. “High Absorption Rate”

– The steel-clad wire sheath protects calcium from premature reaction, allowing deep injection into the ladle.

– Typical calcium yield exceeds “15-30%”, far higher than powder or lump additions.

2. “Precision & Consistency”

– Controlled feeding speed ensures uniform dispersion, avoiding excessive evaporation.

– Adjustable wire composition (e.g., Ca + FeSi blends) for tailored treatment.

3. “Cost Efficiency”

– Reduces calcium waste compared to traditional methods.

– Lowers refining time and energy consumption.

4. “Improved Steel Properties”

– Cleaner steel with fewer inclusions → Better ductility, toughness, and surface quality.

– Enhanced castability in continuous casting operations.

Why Buyers Should Choose Our Pure Calcium Cored Wire?

– “High-Purity Calcium (>98%)” – Ensures effective metallurgical reactions.

– “Customizable Diameter & Length” – Adaptable to different furnace sizes.

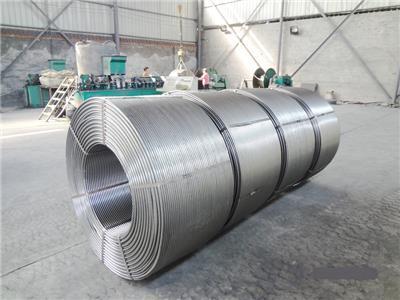

– “Sturdy Steel Sheathing”– Prevents breakage during feeding.

– “Technical Support” – Our experts assist in optimizing feeding parameters for maximum efficiency.

Conclusion

Pure calcium cored wire is a “game-changer”in secondary steelmaking, offering unmatched efficiency in inclusion control and desulfurization. For buyers aiming to produce premium steel with lower operational costs, investing in high-quality calcium cored wire is a strategic choice.

Contact us today: to discuss how our pure calcium cored wire can enhance your steelmaking process!