Introduction

Calcium-coated cored wire is a critical material in modern steelmaking, primarily used for deoxidation, desulfurization, and inclusion modification. Its seamless design ensures precise calcium delivery into molten steel, improving efficiency and reducing waste. This article explores its functions and provides key criteria for selecting high-quality products.

Functions of Calcium-Coated Cored Wire in Steelmaking

1. Deoxidation

– Calcium (Ca) reacts aggressively with oxygen (O) to form calcium oxide (CaO), reducing dissolved oxygen in molten steel and minimizing porosity in final products.

2. Desulfurization

– Calcium converts sulfur (S) into calcium sulfide (CaS), which floats to the slag layer, enhancing steel cleanliness and mechanical properties.

3. Inclusion Modification

– Calcium alters the morphology of non-metallic inclusions (e.g., alumina, Al₂O₃) from hard, angular particles to softer globular calcium aluminates, improving machinability and fatigue resistance.

4. Alloy Yield Improvement

– The seamless coating prevents premature reactions, ensuring higher calcium absorption rates (typically 15–30%) compared to powdered additives.

How to Select High-Quality Calcium Cored Wire

1. Core Composition

– Opt for wires with high-purity calcium (≥98%) and controlled trace elements (e.g., low Al, Si). Some advanced products include Ca-Fe or Ca-Si alloys for better stability.

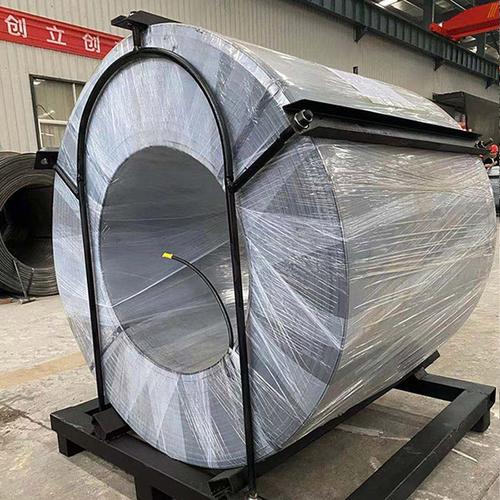

2. Coating Integrity

– Seamless steel jackets (thickness: 0.3–0.6 mm) prevent air/moisture ingress and ensure smooth feeding. Check for uniformity via visual inspection or ultrasonic testing.

3. Dimensional Accuracy

– Standard diameters (e.g., 9–13 mm) with tight tolerances (±0.2 mm) ensure consistent feeding speeds. Verify spooling quality to avoid tangling during deployment.

4. Technical Specifications

– Calcium content: ≥30% by weight (varies by grade).

– Linear density: 200–300 g/m (affects dosing precision).

– Melting point: The coating should withstand pre-feeding temperatures without cracking.

5. Supplier Reliability

– Choose manufacturers with ISO 9001 certification and third-party test reports (e.g., SGS). Request batch-specific chemical analysis certificates.

6. Performance Testing

– Pilot trials in steel plants can evaluate dissolution rates and inclusion modification efficiency. Monitor slag composition and steel cleanliness post-treatment.

Conclusion

High-quality calcium cored wire significantly enhances steel quality by optimizing deoxidation and inclusion control. Selecting the right product requires attention to composition, physical properties, and supplier credibility. Partnering with reputable manufacturers and conducting rigorous testing ensures optimal results in industrial applications.