Calcium silicon cored wire, generally speaking, it is also called CaSi cored wire by industry insiders. According to its name, we can understand clearly that it is a kind of wire products wrapped with steel strip and applied in the industry field. Its design is very ingenious and it is effectively for steel industry to add calcium and silicon into liquid steel in order to improve the performance of steel.

Advantages And Features of Calcium Silicon Cored Wire

There are some unique features and advantages for calcium silicon cored wire amongst these cored wires, such as precise addition, environmental protection, uniform distribution and so on.

Distributed Evenly

It is beneficial for the uniform distribution of alloying elements to use calcium silicon cored wire in the molten steel. It ensures that silicon and calcium are evenly dispersed and results in a homogenous composition. It is crucial for the uniformity to attain the accordant mechanical and chemical properties in finished product.

Added Accurately

It allows for the accurate addition of alloying elements to molten steel. This precision is accomplished depending on the cored wire is fed into the molten steel directly. It ensures that the desired amount of Ca and Si is introduced at the optimal point in the process.

Operated Easily

Calcium silicon cored wire simplifies the alloying process. It is easy to operate and can be fed into the molten steel by wire feeding machine. Meantime, it means reduce the need for manual intervention. This ease of operation not only improves safety by reducing the opportunities that direct contact with high temperature materials but also enhances productivity by simplifying the process.

Increased Yield

The use of calcium silicon cored wire enhances the recovery rate of the added elements. Because the wire is introduced deep into the molten steel, it ensures that calcium and silicon are thoroughly dissolved and distributed. This high recovery rate means that less material is wasted, the overall yield of the production process is increased.

Optimized Performance

It allows for accurate control over the shape and distribution of inclusions in molten steel by utilizing calcium silicon cored wire. It improves the steel’s mechanical properties, such as strength and toughness, meanwhile, it also enhances its machinability. The process makes the steel more reliable and easier to process.

Environmentally Friendly

The use of calcium silicon cored wire contributes to environmental protection and energy savings. By improving the efficiency of alloying element addition, it reduces the amount of materials and emissions. What’s more, this technique can also reduce energy consumption by minimizing other corrective measures.

Calcium Silicon Cored Wire Properties

When it comes to CaSi cored wire, we have to introduce its properties. Frankly speaking, calcium silicon cored wire has a lot of distinctive characteristics. These are as follows:

Firstly, it is conducive to reduce the content of oxygen and sulfur in molten steel, thereby, it improves the quality. And it can change the shape of inclusions to improve the processability.

Moreover, it is difficult for calcium silicon alloy to lose or spill during using or transportation process, it is all thanks to the core structure.

Finally, it can be applied in the production of low alloy steel, high quality steel, stainless steel and some other steels.

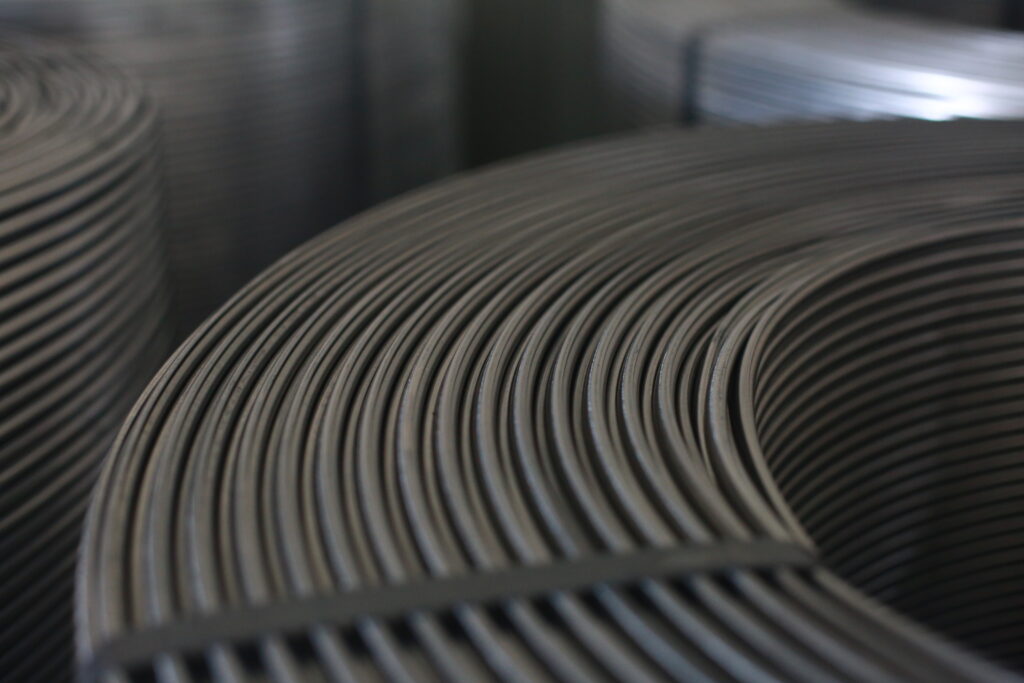

Calcium Silicon Cored Wire Production Process

In terms of production process, if you do not do relevant job, you will be confused about it. Because it is sophisticated relatively.

And it requires a lot of processes to accomplish the goal that manufacture the high-quality finished product.

Now, we will introduce it briefly.

Concretely speaking:

First of all, you should prepare the premium raw material. It includes but not limited to: steel strip, calcium silicon alloy, meantime, you should adjust the machine.

Next, it is time to produce. During the production process, calcium silicon is uniformly filled into preprocessed steel strip via wire feeding machine. And it is paramount for ensuring the quality to wrap and seal.

Last but not least, you should make the package clean and ensure that calcium silicon cored wire is inspected by formal inspection agency.

Looking at the whole production process, it is highly automated. And it is an environmentally friendly production process.

Importance of Calcium Silicon Cored Wire

With the development of domestic steel industry, calcium silicon cored wire is more and more necessary in steel industry. The reason why it is necessary is specially reflected in the following points.

To begin with, as we narrative above, calcium silicon alloy is primeval raw material for calcium silicon cored wire. As we all known, calcium element has a strong deoxidation and desulphurization ability.

In steel industry, it can be used to remove oxygen from molten steel, notwithstanding its content is lower relatively than silicon in calcium silicon cored wire. At the same time, it can also improve the some performances of steel, such as toughness, hardness, hot working performance, cleanliness, etc.

Besides, in order to adapt to plenty of sophisticated applications, some insiders recommend to add appropriate amount of calcium silicon cored wire during the production process. To achieve the relevant goal via its all kinds of properties we mentioned above.

Calcium Silicon Cored Wire Market Prospect

In general, steel industry is the main application area for calcium silicon cored wire. For foreign market, steel production changed slightly in the recent years. On the contrary, for domestic market, demand for high-quality steel is increasing. Thus, in summary, the overall calcium silicon cored wire market will keep slight growth in the future.

Why Choose JINLI GROUP

First of all, we, JINLI GROUP, is a leading manufacturer of various cored wires and steelmaking related products, such as calcium silicon cored wire, calcium iron cored wire, calcium carbide, etc.

Secondly, we provide the high-quality products with the best rate for our clients. And our customers are also satisfied with our after-sales service.

In addition, due to natural geographical advantage, our freight is cheaper than some other inland cities.

Last but not least, we guarantee the quality of product that produced by JINLI GROUP is superior and inspected without any problems.

If you have any needs, please contact us without any hesitation!