Pure Calcium Cored Wire: An Essential Tool in Modern Steelmaking

In the intricate and demanding world of secondary steelmaking, the ability to precisely control the composition and morphology of molten steel is paramount to achieving high-quality final products. Among the various technologies developed for this purpose, the injection of cored wire stands out as a highly effective method.

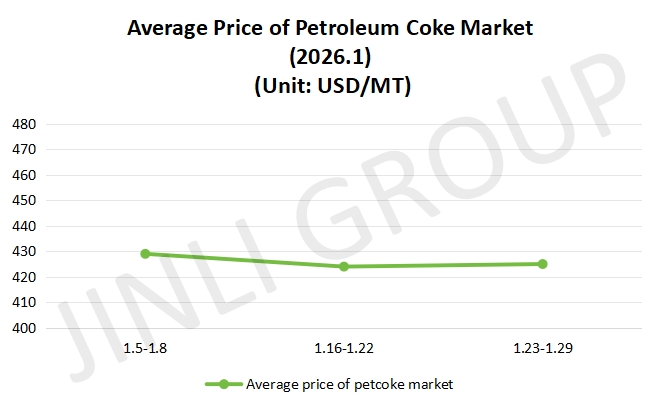

Petroleum Coke Price Monthly Analysis 2026.1

In January 2026, petroleum coke prices are shaped by ongoing shifts in demand, supply chain factors and global economic conditions. This analysis examines the key elements driving price changes this month and offers a concise overview of the market’s current status and potential trends for the near future. Pet

Calcium Solid Wire: A Focused Tool for Specialty Steel Applications

Abstract: While less common than cored wire, pure calcium solid wire serves as a specialized tool in secondary steelmaking. This article details its unique characteristics, updated application data, and niche roles in the production of ultra-low sulfur steels, certain stainless grades, and precision alloying. 1. Definition

Calcium Ferrosilicon Cored Wire: Precision Engineering for Modern Ladle Metallurgy

Abstract: Calcium treatment, primarily administered via cored wires, is a critical secondary refining process for producing high-quality steel. This article examines the latest advancements, performance data, and application trends of Calcium Ferrosilicon (CaFeSi) cored wires, focusing on their role in inclusion modificatio

Rare Earth Ferro Silicon Magnesium Alloy Nodulizer

Introduction Ferro silicon magnesium, as its name indicates, it is mainly composed of magnesium, iron, silicon and some other elements. Generally speaking, it can be used as a nodulizing agent or an additive in cast iron and steelmaking industry. It is beneficial for graphite in nodular cast iron to crystallize the

What is Calcium Silicon Cored Wire?

Calcium silicon cored wire is abbreviated as CaSi cored wire and mainly used in steel industry. It plays a vital role in this industry. It can be demonstrated by the following points, like change the inclusions, reduce the costs, remove detrimental elements, improve the performance and properties, etc. Wire Feeding

Global Cored Wire Market 2025: A Landscape of Growth, Specialization, and Regional Dynamics

Introduction: The Backbone of Modern Steelmaking As we progress through 2025, the global cored wire market remains a critical yet dynamic component of the metallurgical industry. Serving as a precision delivery system for alloying agents and treatment materials—such as calcium, silicon, calcium-silicon, magnesium, and rare

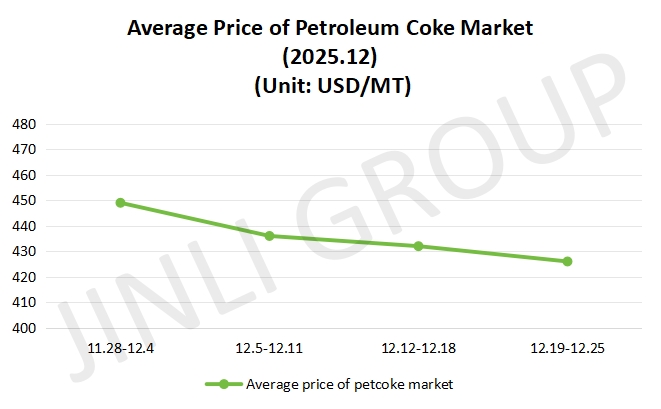

Petroleum Coke Price Monthly Analysis 2025.12

As December 2025 progresses, petroleum coke prices continue to reflect market adjustments driven by supply and demand factors, economic shifts and production changes. This analysis outlines the key influences on pricing during the month, offering a snapshot of the current market situation and providing insights into

The Hidden Alchemist: How Calcium Metal Transforms Modern Steel

Walk through any modern steel mill, and you won’t see ingots of gleaming silver metal labeled “calcium.” Yet, in the final, crucial stages of producing high-quality steel, metallic calcium performs what can only be described as industrial alchemy. It is a secret weapon, a microscopic surgeon that operates

Calcium Carbide in Modern Metallurgy: From Fundamental Reactions to Industrial Precision

Introduction: The Versatile Workhorse of Steelmaking Calcium carbide (CaC₂) stands as one of the most transformative compounds in metallurgical history, bridging the gap between bulk chemistry and precision processing. This grayish-black crystalline substance, discovered accidentally by Thomas Willson in 1892 while attempti